benches 2020

When the first architects built Stonehenge, they diverged evolutionarily from Homo Sapiens, and still do today. Some can even act as aliens today. And because we love all such aliens who also have a completely clear opinion, we will do everything to materialize their ideas and bring them to life. One such is the great architect Jiří Poláček, and we took on his proposal for benches for the public transport terminal in Chrudim.

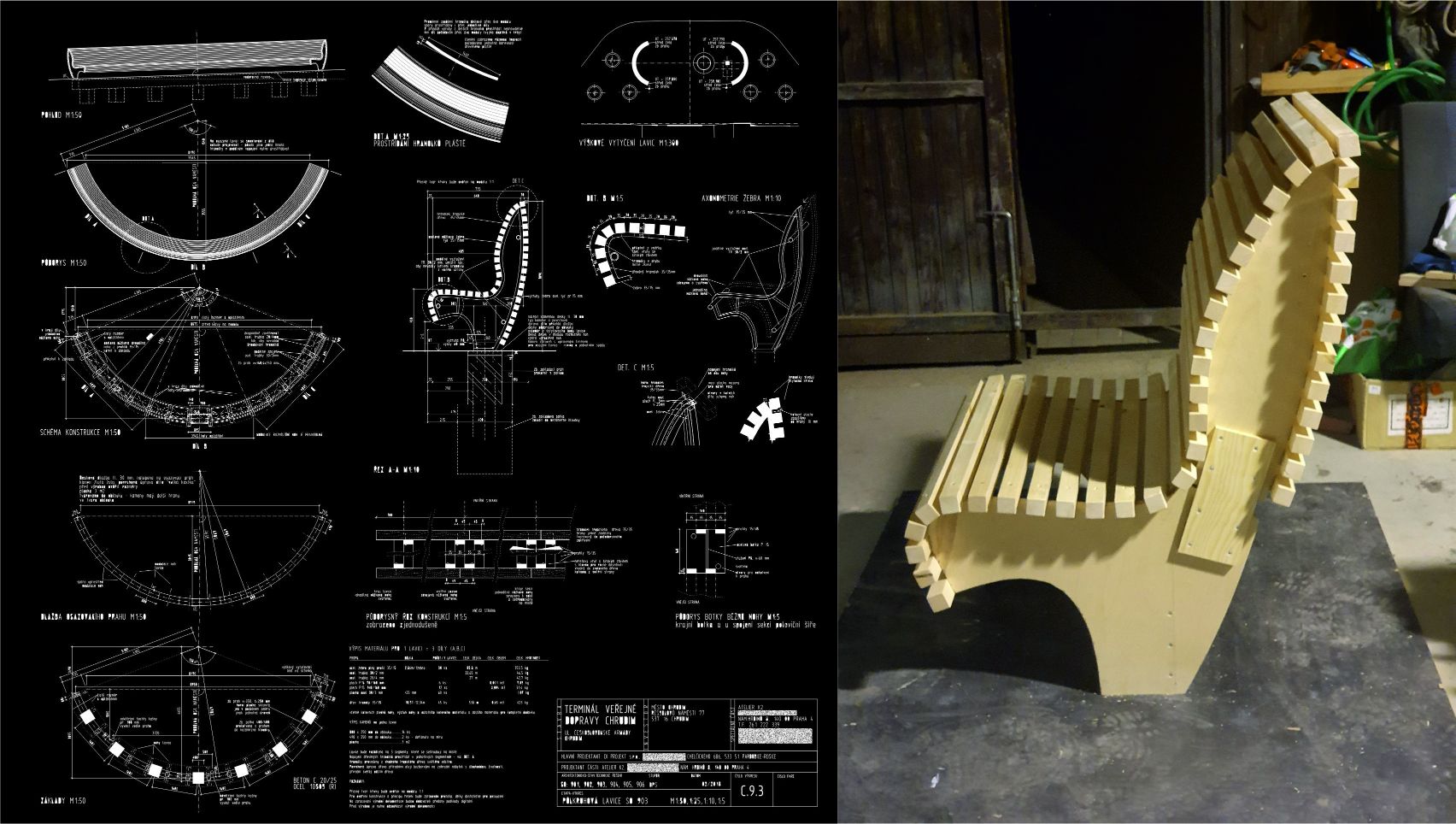

Even though all experts, friends and other insiders told us that it couldn’t be done, or that it was complicated and risky, after long discussions with the architect and the client, we got down to it. We modified the structure, chose slightly different materials, did trials and tests and could start producing the seemingly impossible. However, it is not a guide for other architects, who sometimes absolutely trivially insist on their “visualizations”, because it is not always possible to do it this way and sometimes it requires a number of considerable concessions on both sides.

So that I don’t write essays or a seminar, from now on I will only use the procedure and list. Initiates and experts will understand, hopefully it will help others at least a little to zoom in on the content of some photos.

- Intensive communication with the author, understanding of the intention

- Shape correction, or profile – physical testing on the sample – sitting and “rolling” tests

- Improvised bending test, switch / drag calculation

- Editing of drawings for the production of steel structures

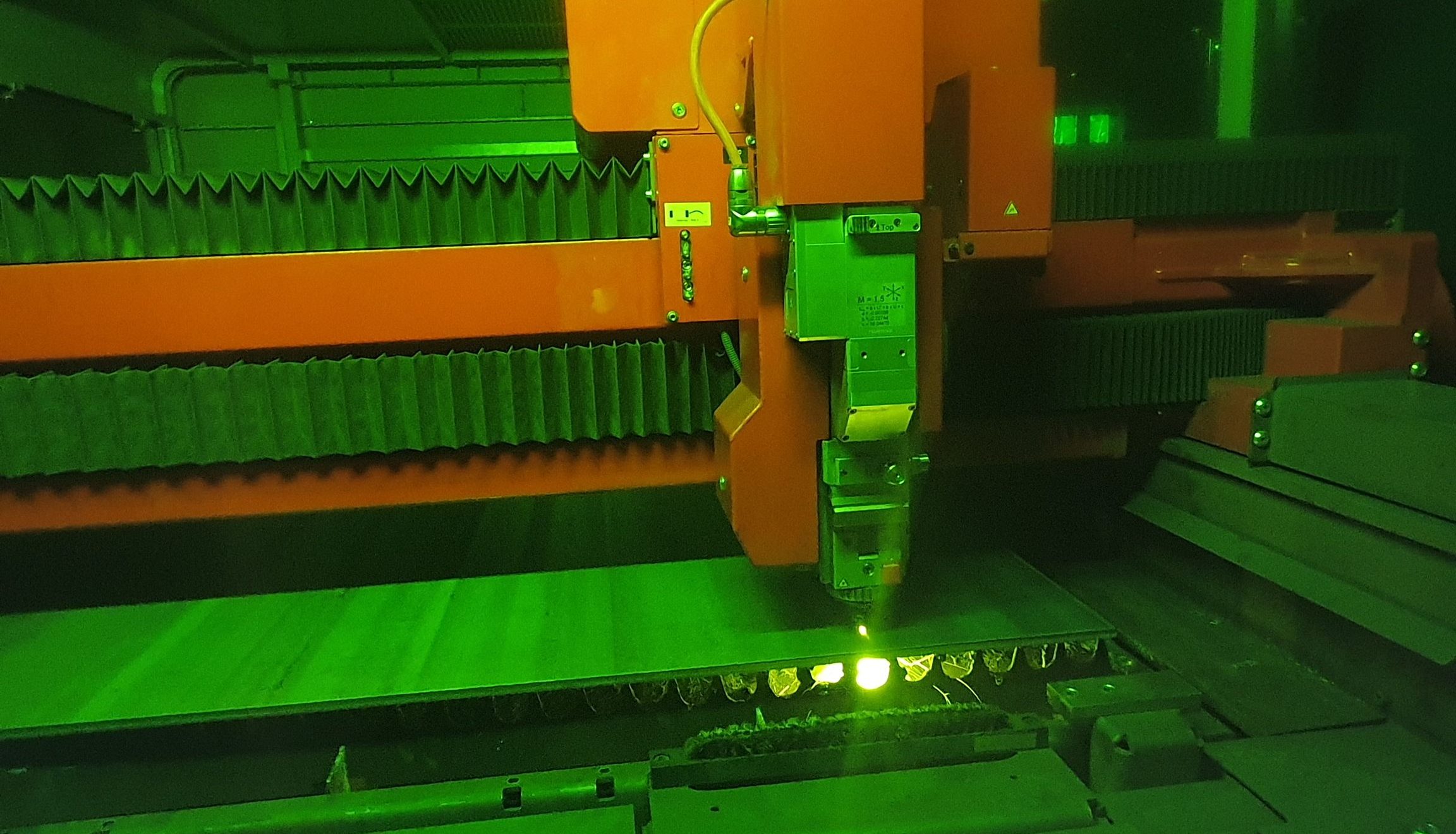

- Fiber laser cutting, press brake bending, welding, grinding, galvanizing, komaxit

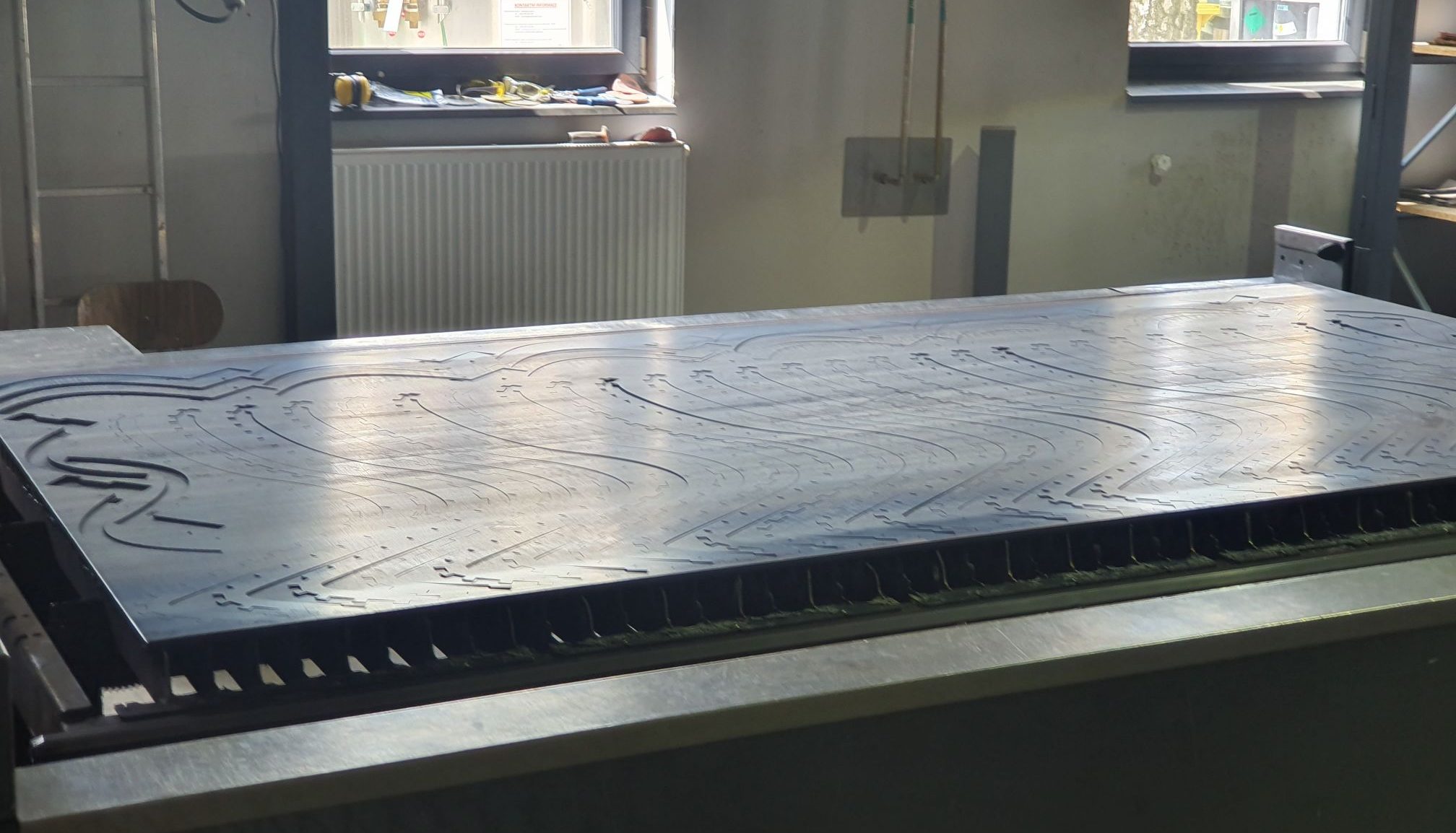

- NC milling of 3D molds for bending, different tilt angles, different radii

- Production of stainless steel steaming boxes for slats 3 m long

- Classification of battens according to the angle of the shoots

- Steaming and bending itself

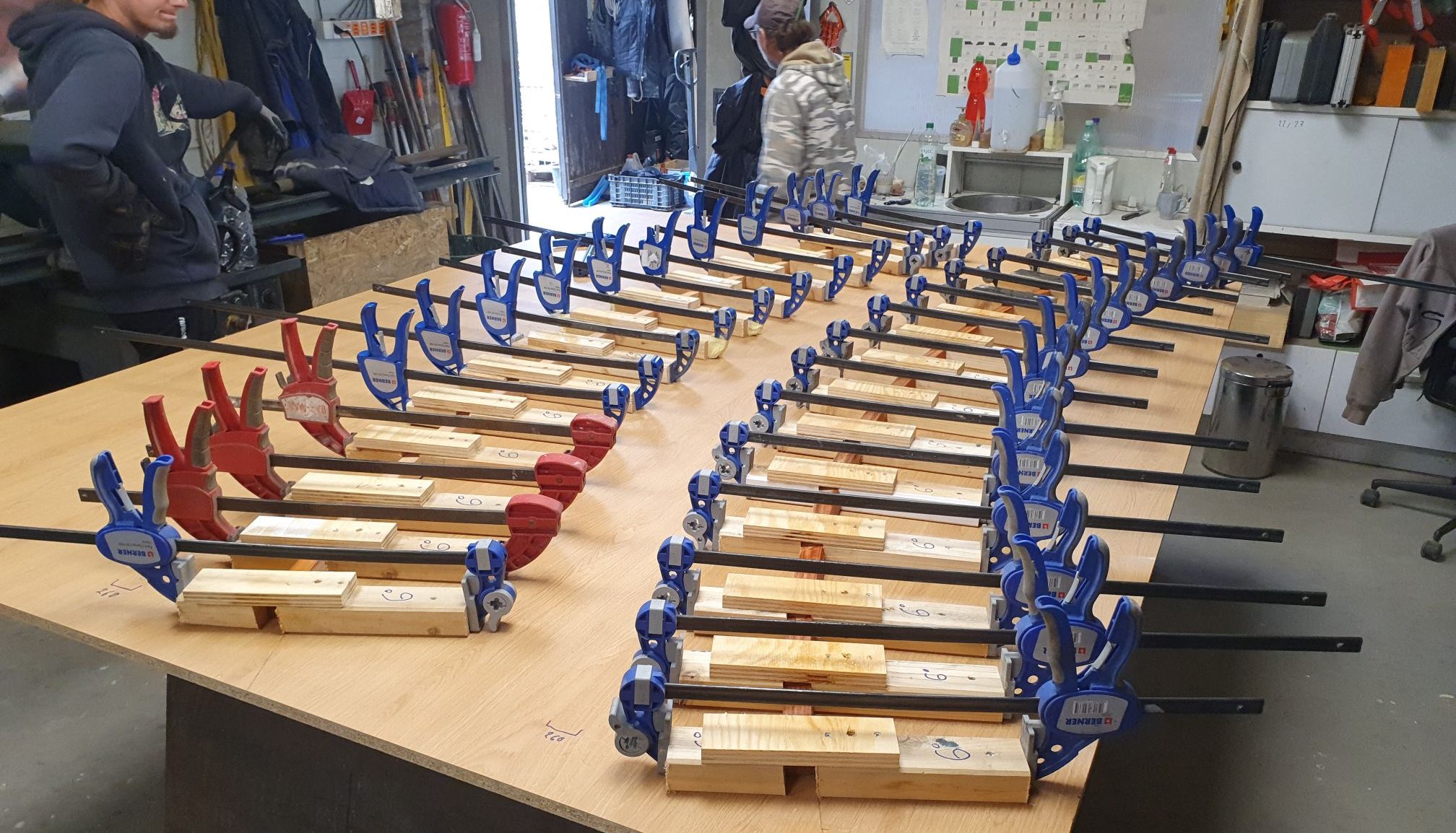

- Storage in already prepared constructions for memory fixation

- NC milling of transport and assembly ribs (binders)

- On-site anchoring of structures, precise shortening, hidden joints, grinding, oiling

In numbers:

- 1760 kg of iron

- 6720 welds and their regrinding

- 1,500 m of steamed and bent tropical wood slats

- 0.72 m3 made of tropical wood

- 11,000 strong stainless steel screws

- 360 holes and chemical anchors for granite

- 6 months of work by the whole team

Do you like the result? Write us.